>> Hướng dẫn đặt hàng trực tuyến

Giá có thể thay đổi chưa kịp cập nhật, xin vui lòng liên hệ trực tiếp để biết giá

Tên thiết bị: Primacoustic FlexiFuser High Freq Flutter Diffuser Panel

Model: Primacoustic FlexiFuser High Freq Flutter Diffuser Panel

Thương hiệu: Primacoustic

Hình ảnh thiết bị như hình chụp

FlexiFuser - Combination Diffuser

The Primacoustic FlexiFuser is an innovative acoustic device that combines diffusion with absorption to disperse high frequency flutter echo and control primary reflections at the same time.

Measuring 24″ x 48″ (60.96cm x 121.92cm), the FlexiFuser is equipped with six variable pitch slats that span the full top-to-bottom height. These are rotated at varying angles to disperse high frequencies, creating the desired energy spread that best suits the room and seating position. Behind the slats is a high-density 2″ (5.08cm) thick acoustic panel that effectively absorbs directional energy down to 250Hz while eliminating resonant build-up behind the slats.

Made from hard, heavy wood composite for maximum reflection, the Flexifuser ships flat to save freight. Assembly takes less than 15 minutes using standard household tools. The 3″ (7.62cm) wide slats can be fixed in a predetermined position using the supplied guide pins or left free to rotate after assembly is complete. The absorptive acoustic panel is made from 6lb high-density glass wool for even absorption right down into the critical lower mid range zone. Micromesh encapsulated with resin hardened edges, the Broadway panel is then covered in an architecturally neutral grey fabric that easily integrates into most room décors.

FlexiFusers are typically mounted behind the listening position in an array of three or more units that span the width of the work area and are hung in place using a simple French cleat. Once in position, they introduce a sense of space and air into the room while absorbing powerful reflections, standing waves and bothersome flutter echo. This makes the Flexifuser particularly well suited for control rooms, more demanding home theatres and smaller studios where near-wall primary reflections are of utmost concern.

Applications

FlexiFuser Rear Wall Placement

The Flexifuser can add a sense of space and air in small rooms by spreading sound energy around.

FlexiFuser Corner Placement

The Flexifuser makes it easy to change the acoustics in the studio and adapt to various instruments.

FlexiFuser Variable Acoustics In The Studio

The most common placement for diffusers is at the rear of the room, spanning the width of the work area.

Specifications

The FlexiFuser is a combination diffuser and absorber that helps eliminate standing waves and flutter echo without over deadening the room.

The innovative design begins with six variable pitch slats (A) that can be rotated or set in position to redirect sound energy away from the primary listening space. Behind the slats is a high density 6lb glass-wool absorber (B). This works double duty by eliminating any internal resonance while further absorbing unwanted room reflections. This is augmented with air space behind the panel to increase bass absorption.

The outer frame (F) is made from easy to clean black melamine coated MDF wood composite. The FlexiFuser ships flat in kit form to save freight costs and assembles in about 30 minutes using standard household tools. Once together, the device is wall mounted using the supplied French cleats. The FlexiFuser comes with a grey acoustic panel.

| Order Number | Z840-1135-08 |

| Frame Material | Black melamine laminated MDF outer & slats |

| Dimensions | 24” (610mm) x 48” (1219mm) x 8” (203mm) |

| Panel Material | Formed, semi-rigid inorganic glass fibers; 6.0 lbs. pcf. (96 kg/m3) |

| Weight Assembeled | 46.8 lbs (21.2 kg) |

| Fabric Facing | Acoustically transparent polyester, Grey only |

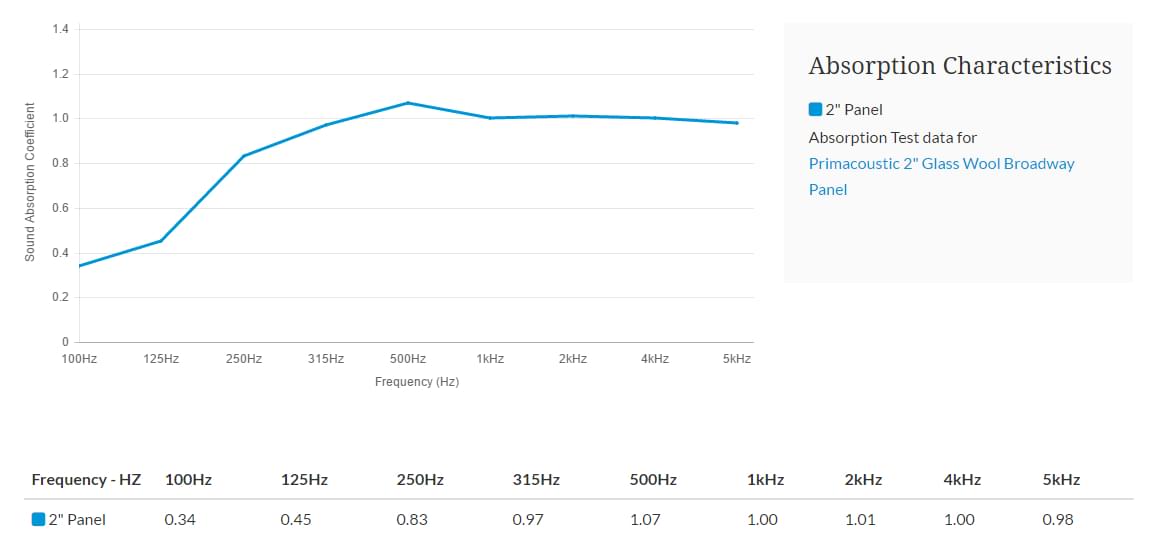

Absorption Coefficients

How to Use

The FlexiFuser is shipped flat in a box to save space and costly freight charges. All of the parts you need to put it together are inside including dowels, screws and mounting hardware. Standard household tools are all you need to build a FlexiFuser. Most folks find that it takes about 25 minutes to assemble following the simple step by step instructions. If you like, you can download the assembly manual by clicking this link to the FlexiFuser user guide. Once assembled, the FlexiFuser employs a French cleat as the wall hanging support mechanism. One cleat is mounted on the wall surface and the FlexiFuser simply hangs in place.

The FlexiFuser can be placed anywhere in a room to effectively diffuse sound energy, but below we have outlined the most effective surfaces to treat with diffusers. The determining factors for placement within a room are dependant on your room layout and what you want to achieve. A huge benefit to the FlexiFuser is the adjustability after installation, where your rooms acoustic response can be altered to suit by positioning the FlexiFusers vertical reflectors. This way you can move from a diffuse environment to a more absorptive space as required.

FlexiFusers are usually mounted in a row of three or more units to cover the width of a listening area or sweet spot. FlexiFusers can also be stacked to cover an entire wall for even greater control of room response between reflective diffuse and absorptive.

Application 1 - Rear Wall Placement

The most common placement for diffusers is at the rear of the room where direct sound coming from the monitors can pose problems by creating powerful reflections. For great results, most designers will gang several FlexiFusers together that will span the entire work area behind the listening position. These are usually centered at ear height or slightly higher to maximize the ‘width’ of listening space.

Application 2 - Corner placement

In smaller rooms, the FlexiFuser can add a sense of space and air in by spreading sound energy around the room. The variable slats allow you to redirect the energy away from the primary listening space and use the natural room boundaries to diffuse the high frequency energy. The internal acoustic panel will also help by absorbing low frequencies – a common problem in small rooms.

Application 3 - Variable acoustics

Optimizing the room acoustics for one instrument may not make it ideal for another. For instance, acoustic instruments like violin, cello, acoustic guitar and piano tend to enjoy a livelier space while electric guitars and drums tend to sound better with some room absorption. The FlexiFuser makes it easy to change the acoustics in the studio by simply rotating the slats for more or less reflection.

FlexiFuser Science

- LEDE – Live end, dead end room designs

- Diffusion – breaking up high frequency energy

- Absorption – controlling sound and resonance

- Combined approach – controlling directional frequencies

The concept behind the Flexifuser came from trying to find an affordable way to disperse high frequency energy. High-end diffusers like the Razorblade are extremely expensive to produce and therefore are usually only found in high-end rooms. By combining simple diffusion with absorption, the Flexifuser delivers exceptional performance.

LEDE – Live end, dead end room designs

The question is simple: Why diffuse energy in the first place? Why not simply absorb it? Well, way back in the dark ages of recording (circa 1960) many studios were entirely treated with absorptive materials making them sound dead and listless. Engineers quickly realized that listening in an artificial environment results in recordings that did not translate well into the ‘real world’.

Sometime in the 1970’s a new studio design concept came about that treated half the room with absorptive panels (dead-end) while the other half was totally untreated (live-end). This became known as the LEDE or a ‘live-end, dead-end’ room design. The intent was to allow the engineer to make critical decisions such as special placement by eliminating the ambience in the dead end, while allowing sound to reflect at will in the live end. Although better than an ‘anechoic chamber’, problems still persisted.

Diffusers began to find their way into studios during the 1980s as a means to help eliminate flutter echo and eliminate powerful primary reflections. Over the years, the LEDE concept evolved to where today, most rooms tend to have a greater degree of absorption at the source end of the room, while the receive end is left relatively live with the aid of natural and artificial diffusers.

Diffusion – breaking up high frequency energy

There are many types of diffusers and they pretty much have one thing in common: they feature some form of irregular pattern designed to reflect energy back into the room at various angles by breaking up directional energy.

Some diffusers such as the Razorblade are designed in such a manner to ensure all frequencies are broken up evenly via a carefully designed phase trap. These are painstakingly difficult to produce and end up being quite expensive. At the other extreme are products like the Radiator that employ a basic grid design that cause sound arriving at oblique angles to randomly spread into the room. These are easier to build, not quite as effective but are considerably more affordable.

The Flexifuser sits in between. It employs a series of variable pitch slats that can be rotated so that sound can be deflected away from the listening position. This increases the sense of space or air in the room. The simple design is particularly cool because you can optimize the dispersion pattern to suit the seating position.

Absorption: controlling sound and resonance

Where the Flexifuser differs is that it combines diffusion with absorption. Think of it like a two way speaker where high frequencies are generated by a tweeter and lows by a woofer. In this case, highs are dispersed by the variable pitch slats and the lows are absorbed by the acoustic panel in behind.

The acoustic panel itself is a custom cut 2″ thick Broadway panel. Because it is offset from the wall with an air gap, the low frequency performance is extended by about an extra half octave. This means that it will be 80% effective down to 250Hz putting well below what most consider to be the directional frequency zone (above 300Hz). Any high frequencies that get past the slats will be absorbed and any sound that gets trapped behind the slats that could potentially cause resonance will also get taken out.

Combined approach: controlling directional frequencies

As mentioned above, acousticians generally agree that sound tends to beam or be directional above 300Hz. The task of a diffuser is in fact to diffuse this energy. Since high frequencies contain less energy than their lower counterparts, they are much easier to manage. Therefore, diffusing high frequencies above 1000Hz is not difficult. Where things get to be a challenge is down low. By using simple quarter-wavelength calculations, you need a device that is 8″ deep to diffuse 400Hz.

It is important to note that without mass, sound will pass right through. For instance a plastic bag will not contain sound even though it can contain air. It is for this reason that the Flexifuser in made from a heavy, wood composite; when sound hits the slats, most of it will reflect back into the room.

| Diffuser Depth (inches) | Low frequency cut-off (Hz) |

|---|---|

| 1″ | 3.2k Hz |

| 2″ | 1.6k Hz |

| 3″ | 1.2k Hz |

| 4″ | 800 Hz |

| 6″ | 600 Hz |

| 8″ | 400 Hz |

| 12″ | 300 Hz |

| 16″ | 200 Hz |

| 24″ | 150 Hz |

| This table shows the anticipated cut-off point of a diffuser using quarter-wavelength calculations. This assumes a relatively hard surface with sufficient mass to reflect energy back into the room. Some diffusers are designed to be grouped to create larger wells to lower their effective range. This table assumes a single device. | |

Basic math will tell you that a 4″ deep device will diffuse energy above 800Hz or one octave above. But to effectively diffuse energy down to 200Hz, one would have to produce a diffuser that is 16″ deep which is impractical. This is why the Flexifuser is so cool. Instead of trying to diffuse the energy below the directional frequency, it is absorbed using the acoustic panel.

And at less than half the price of a Razorblade, you truly are getting exceptional value for your dollar!

Chúng tôi vận chuyển tận nơi trên toàn quốc, nhận hàng thanh toán tiền cho người giao hàng. Hà Nội nhận hàng trong ngày. Các tỉnh khác nhận hàng 1 -2 ngày

Liên hệ: 0946.112.556 - 0320.2.223.225 - 0320.3.841.496.

© Bản quyền thuộc về công ty TNHH VNM

www.dienmayviet.com.vn www.dienmayviet.vn

Nhà phân phối trên toàn lãnh thổ Việt Nam. Miễn phí vận chuyển tận nơi trên toàn quốc, nhận hàng thanh toán tiền

Thiết bị được phân phối bởi: Công ty TNHH MTV Phát Triển Công Nghệ Máy Tính VNM

Hotline: 0946.112.556 - 0320.2.223.225 - 0320.3.841.496

E-mail: Product.vnm@gmail.com

Yahoo online: vnm_colorvis_sale

Hàng chính hãng, Full box, new 100%

Công ty TNHH VNM. Nhà phân phối sản phẩm chính hãng

Pin laptop chính hãng, sạc laptop chính hãng, pin máy ảnh chính hãng, sạc máy ảnh chính hãng, pin máy quay chính hãng, sạc máy quay chính hãng. Vui lòng truy cập www.chinhhangpin.com hoặc www.pinoriginal.com

Website trực thuộc quản lý của công ty TNHH VNM:

www.dienmayviet.vn

www.dienmayviet.com.vn

www.chinhhangpin.com

www.pinoriginal.com